The need for a skilled workforce is high and one Oklahoma is looking to reduce.

“Employers are increasingly looking to hire staff with cross-disciplined skill sets. That doesn’t mean they’re recruiting jacks- or janes-of-all-trades that are masters of none. Although they typically have a specialty, these professionals either have expertise in other areas related to their core disciplines, or are adaptable enough to learn what they need to get the job done,” states Entrepreneur Magazine.

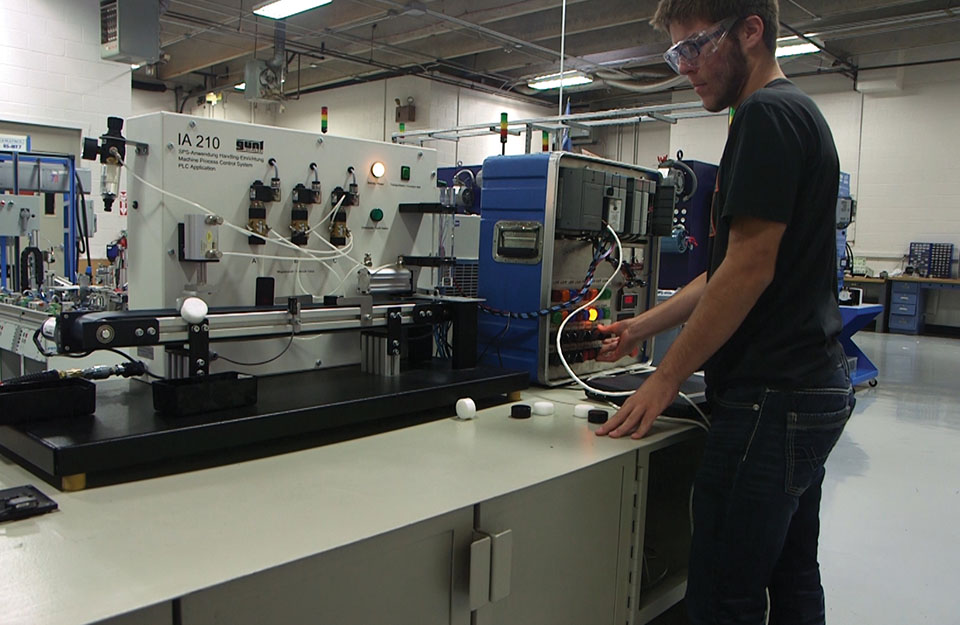

Central Tech’s Mechanical Engineering Systems is one such program offering multiple disciplines and revising the name this fall to Electromechanical Systems to better reflect what the class teaches. Electromechanical Systems is a combination of Electronics + Electricity + Pneumatics + Mechanics. Electromechanical technicians operate, test and maintain robotic, unmanned, automated, or electro-mechanical equipment by combining the knowledge of mechanical technology with electrical and electronic circuits.

“It’s a class built to teach students industrial automation and industrial technology. There’s such a need for industrial maintenance mechanics out in the field, they’re aging out and so they’re just desiring more and more young hands to get in. The class teaches basic electrical theory all the way up to programming PLCs and process control loops,” says instructor Joe Carter.

Students at Central Tech learn skills quickly since 75% of the curriculum is project-based and hands-on. They learn about automated manufacturing processes and how things work while training on leading PLC equipment.

Students who complete the course can become certified as an Electronics Assembler or General Electronics Technician (endorsed by IPC-Association Connecting Electronics Industries, and/or Haliburton & Cameron Measurement Systems [CMS]).

“I was very impressed with the instructor and I was also very impressed with the facility and the curriculum and the manner in which they teach. One of the big pieces for our company is safety and I really like that there’s a big emphasis on that,” says Joe Popplewell, operations manager for Seaboard Foods.

There is a big misconception of working in a factory/manufacturing environment. Nick Pinchuck is the CEO and chairman of Snap-On, Inc., and says, “We think of labor, particularly in a factory, as being dirty and dark. And that’s not the way it is any more. Most of the factories in the United States today are bright and clean. And the machines that are working on those floors are very, very technical. It takes a skilled person to run them, particularly if you are running a complex product line.”

That’s what Central Tech students learn. They take care of the product lines, robotic, and automated systems that keep our industries moving. On top of that, the average starting salary for Central Tech graduates is $18 per hour and according to the Bureau of Labor Statistics the median pay is $25.52 per hour or $53,070 per year. That’s an impressive salary for students coming right out of high school.

Students can choose to study in one to five areas:

Electrical/Electronics Maintenance Technician or Electrical Maintenance Technician Assistant is a great choice for individuals seeking careers in maintaining the manufacturing environment. These courses cover the basics of the maintenance manufacturing curriculum, including: safety, manufacturing fundamentals, tools, basic electricity, basic electronic, motor control, and adapting to the workforce skills.

Electronics Assembler prepares students to read engineering drawings and electronic schematics to assemble electronic products. Students learn electrical safety, proper use and maintenance of hand and power tools, and precision measurements for electronics technicians. Included are proper selection of connection techniques and connectors and fasteners used in constructing electronic circuits and devices along with the troubleshooting, repair, and maintenance of electromechanical devices.

Mechanical Maintenance Technician or Mechanical Maintenance Technician Assistant is for individuals who want to maintain, troubleshoot and repair machinery in an industrial manufacturing environment. Students learn safety rules and regulations, lean manufacturing concepts and principles of welding and machining along with maintenance tools and equipment, schematics and blueprints. Students are taught maintenance and repair of electromechanical devices and mechanical/fluid power transmissions.

Call Central Tech at 918.352.2551 with questions regarding the application process, financial aid, requirements for certification, and when to apply. This course is available in Drumright to adults and high school juniors and seniors. You can also see it first-hand by visiting Central Tech’s Mechanical Engineering Systems (Electromechanical Systems) program during Open House, Sunday, February 14 from 1-4 p.m.