INDUSTRIAL AUTOMATION

Ever wondered how things are made? Like a car for example. You picture it on an assembly line. But who programs all the big machines that make the assembly line work? Industrial automation uses advanced machines to handle most of the work in factories. These machines follow computer instructions that communicate on screens with special codes. And…these machines help factories produce things faster with 3D printers and precision CNC machines that make parts with surgical accuracy. It’s all about making things…like cars…smarter, faster, and more efficient.

MAINTAIN – REPAIR – INSTALL

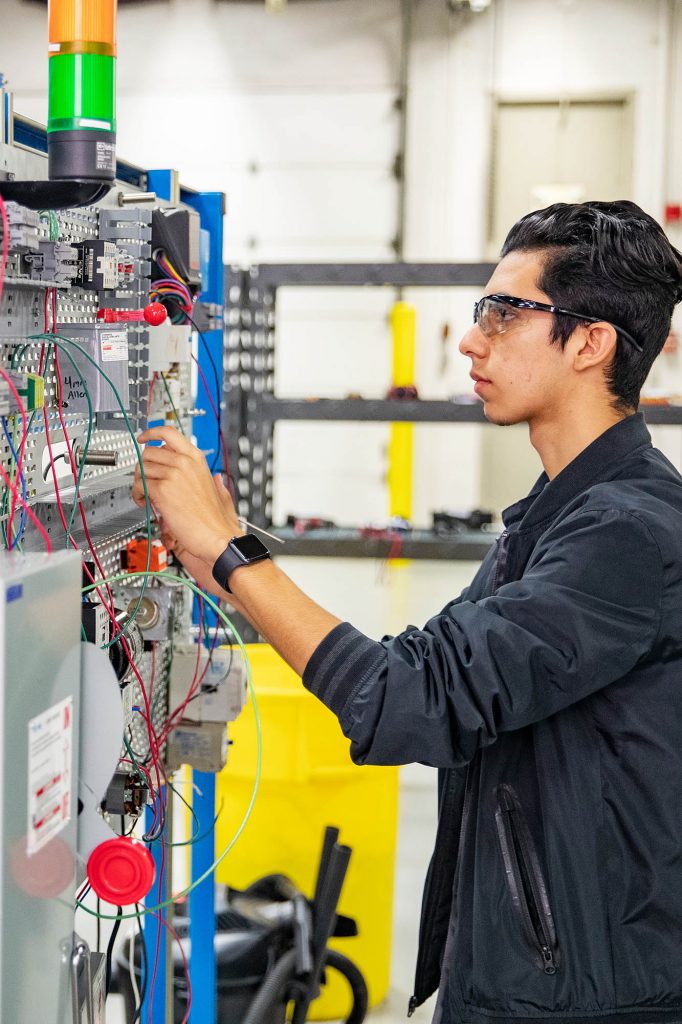

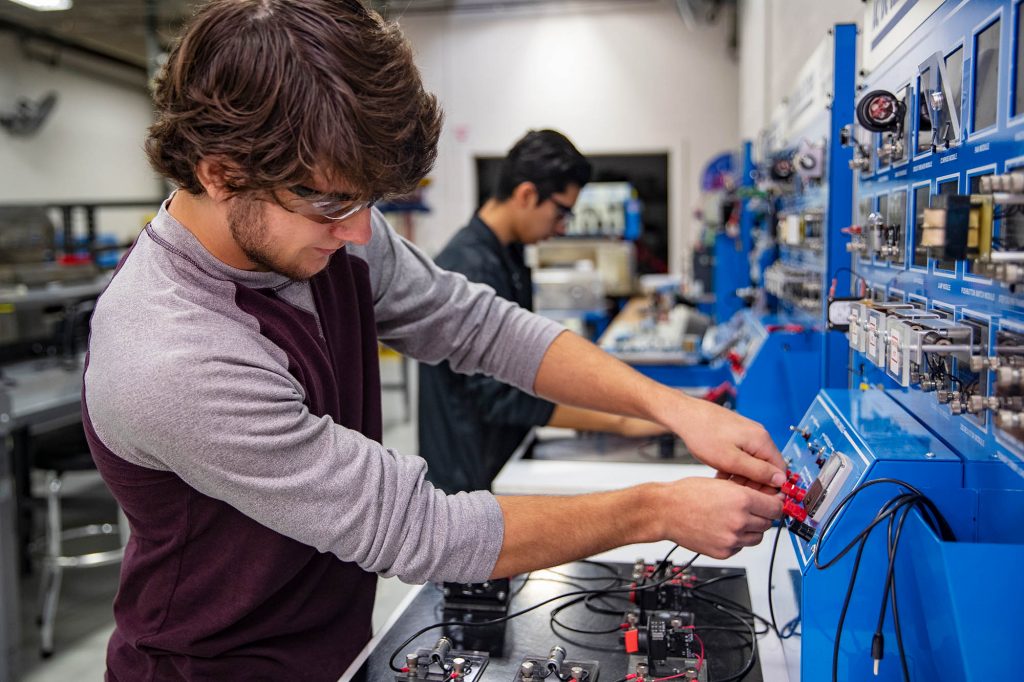

Industrial Automation, commonly called automation technicians or industrial maintenance technicians, play a vital role in todays workforce. As more machines become automated it takes a well-rounded individual in key areas to maintain these machines.

As an industrial automation student, you will learn:

- Basic Electrical Theory/Wiring

- Mechanical Drives Systems (belts, pulleys, gears, bearings, chains, etc.)

- Hydraulic Systems

- Pneumatic Systems

- Motor Control Systems

- Manufacturing

- Machining, Welding

- Programmable Logic Controller

- Variable Frequency Drives

- Safety in Industry

- Tools

- Adapting to the Workforce

Having this diverse skillset enables you to adapt to the needs of the company by being able to install, operate, test, repair and maintain industrial equipment.

This equipment can be found anywhere from a manufacturing facility to oil and gas related fields.

While you’re learning the unique skillsets this class offers, you have the potential to earn industry recognized certificates in the following areas.

- Electric Motor Control Systems

- Electrical Systems Installations

- Electrical Systems 1

- Mechanical Power Systems 1

- Pneumatic Systems 1

- “NC3” Snap-On Meter 596F

Most of our certifications are through Smart Automation Certification Alliance “SACA”. SACA is nationally recognized by several cooperation’s including Rockwell Automation, Schlumberger, Ashley Furniture, Hershey, Kohler, Boeing, and Fanuc

Our Snap-On Meter certification showcases your ability to prove that you can use a digital multimeter safely and effectively. NC3 is the National Coalition of Certification Centers and is a value driven organization. Industry recognized Precision Measuring (PMI) certifications are also available to obtain.

CAN I FINISH THE PROGRAM EARLY?

Yes, this program is designed to be self-directed, adults with the aptitude for and work ethic can complete the curriculum early and start on-the-job training (OJT).

IS THIS A GOOD JOB FOR ME?

Ask yourself these questions:

- Do you like a challenge?

- Do you like to troubleshoot?

- Are you interested in gaining a diverse skillset?

- Do you like to work with your hands?

- Are you interested in a potentially high-paying career?

If you said yes to at least two of the questions, then this is the class for you.

Leaving this program with a diverse skillset, puts you a step ahead in job placement. You can complete this program and start your career in industry!

AUTOMATION TECHNICIAN

PATHWAY

DETAILS

This program is designed for those seeking careers in maintenance in a manufacturing environment. This is the basics of the maintenance manufacturing curriculum. The course covers:

- Safety

- Manufacturing Fundamentals

- Tools

- Basic Electricity

- Basic Electronics

- Motor Controls

- PLC Programming

- Process Control

- Adapting to the Workforce Skills

AREAS OF STUDY

- Safety in Manufacturing

- Introduction to Manufacturing

- Basic Electrical Theory

- Basic Electrical Machines

- Electric Motor Control

- Electro-Fluid Power

- Industrial Electrical Wiring

- Variable Frequency Drives-AC Drive Systems

- Computer Control

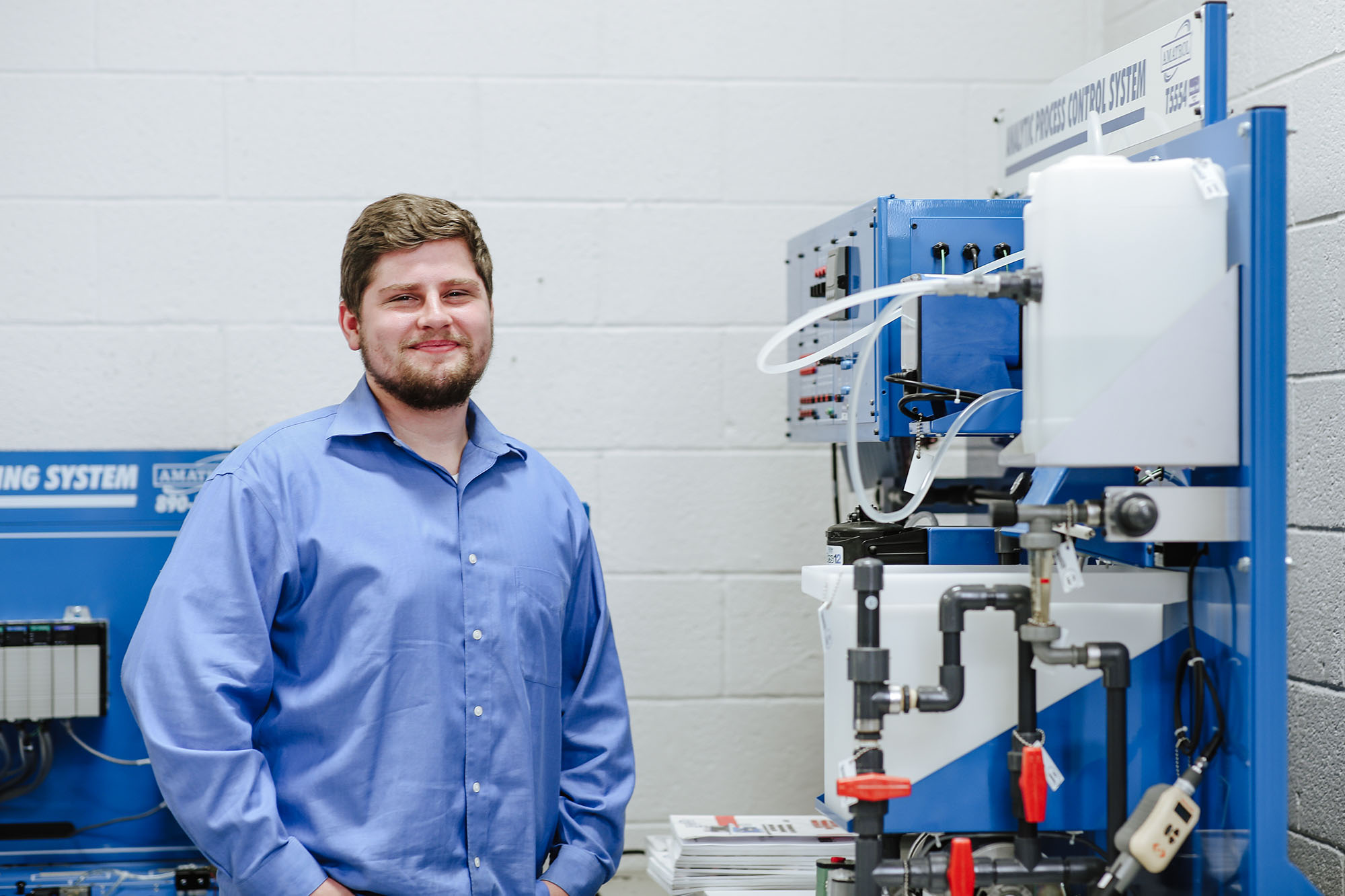

“We hired five students from the previous class. We can’t wait to see our options this year!”

#centraltechAutomation

Also known as industrial maintenance, Automated Robotics students learn to install, operate, test, maintain, and repair industrial machinery. As they develop troubleshooting skills for robotics, programmable controllers, and automated systems, they engage in hands-on lab experience to practice skills learned in the classroom.

LEARN MORE > https://bit.ly/3njxmf4

#centraltechedu #centraltechAutomation

MORE INFORMATION

Overall employment of industrial machinery mechanics and machinery maintenance workers is projected to grow 19% until 2029. With a starting salary of $18-$19/hr and the ability to move up quickly, it’s a good time to join this field.

Our graduates work in many industries including aeronautical, energy (oil & gas), and companies such as Amazon, Webco, Plains, and Michelin. They also work in other industrial environments, including computer and communications equipment manufacturing.

Potential certifications through Smart Automation Certification Alliance (SACA) include:

- Electric Motor Control Systems 1

- Electrical Systems Installation 1

- Electrical Systems 1

- Mechanical Power Systems 1

- PMI Precision Measurements Instrumentation

- Pneumatic Systems 1

- Students: Adult & High School

- Campus: Drumright Only

- Times: Morning, Afternoon, Full Day

- School Year: August-May

Ask about Financial Aid and Scholarship availability.

- Electrical Trades

- Industrial Automation (short-term)

- Machining (short-term)

- Pre-Engineering